MAG-FORM®

Self tapping screws engineered to minimize debris generation when tapping into conventional magnesium die-castings and other low-ductile materials.

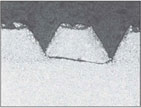

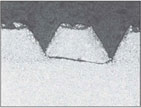

Standard thread-forming screws with a 60° flank angle create excess debris when driven into low-ductile materials. They can easily exceed the ductility limits of the material, causing damage to the formed threads.

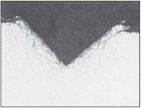

Mag-Form® screws are specifically designed with a broader flank angle to eliminate tapping operations while forming strong threads in conventional magnesium die-castings and similar materials. The design also minimizes debris, making Mag-Form® fasteners the optimal solution for critical applications such as

electronics and air bag modules.

-

-

-

-

- Features

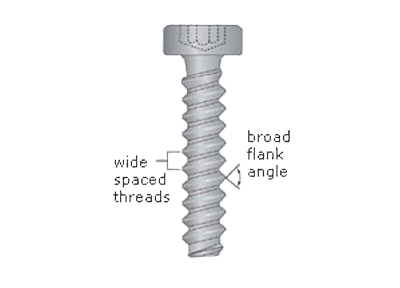

Lobular Configuration

Wide-spaced thread design

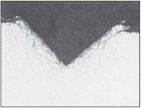

Broad flank angle compresses, rather than roll-forms, threads into the mating material - Benefits

Minimizes debris generation

Forms strong threads in low-ductile materials

Easily removed and reinserted for service in the field

Standard 60° Flank Angle Thread-Forming Screws

May exceed ductility limit of the material, causing damage to formed threads

Mag-Form® Thread-Forming Screws

Compressive action forms strong threads in low-ductile materials- Design Guidelines

Sizes: MG1.0 to MG16

Thread Design: Wide-spaced thread with broad flank angle

Head Design: Can be used with any external or internal head designs

Drive System: Can be used with all systems, including the TORX PLUS® Drive System

Finish: Zinc and chromate to minimize galvanic corrosion

- Features

-

-

-

-

-

-

-

- Features

Lobular Configuration

Wide-spaced thread design

Broad flank angle compresses, rather than roll-forms, threads into the mating material - Benefits

Minimizes debris generation

Forms strong threads in low-ductile materials

Easily removed and reinserted for service in the field

Standard 60° Flank Angle Thread-Forming Screws

May exceed ductility limit of the material, causing damage to formed threads

Mag-Form® Thread-Forming Screws

Compressive action forms strong threads in low-ductile materials- Design Guidelines

Sizes: MG1.0 to MG16

Thread Design: Wide-spaced thread with broad flank angle

Head Design: Can be used with any external or internal head designs

Drive System: Can be used with all systems, including the TORX PLUS® Drive System

Finish: Zinc and chromate to minimize galvanic corrosion

- Features

-

-

-