PLASTORX® FASTENERS

Can be molded directly into plastic, replacing metal stamping and fastener assemblies. Engineered to provide high resistance to rotation and pull-out.

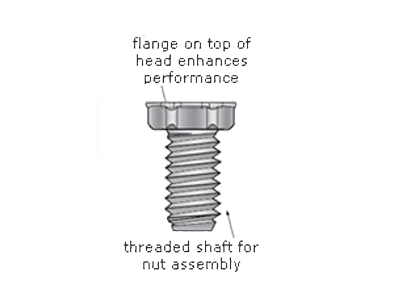

Developed to be molded into plastic and replace metal stamping and fastener assemblies, PlasTORX® studs are engineered to provide high resistance to rotation and pull-out, ensuring a high-performance assembly. Its hex-lobular design helps reduce stress risers, so it can be used in materials susceptible to cracking or breaking.

-

- Features

Hex-lobular TORX® configuration

Flange on top of head

Threaded shank for nut member

Designed to be molded directly into component or carrier strips - Benefits

Allows multiple fasteners to be installed at one time, increasing assembly efficiency

Provides maximum resistance to rotation and pull-out

Ideal for materials susceptible to cracking - Design Guideliness

Sizes: M4 – M12 (#8 – 1/2″)

Lengths: Per customer design

Thread Styles: Machine screw; others as specified

Specials: Completed assemblies available

- Features

-

- Features

Hex-lobular TORX® configuration

Flange on top of head

Threaded shank for nut member

Designed to be molded directly into component or carrier strips - Benefits

Allows multiple fasteners to be installed at one time, increasing assembly efficiency

Provides maximum resistance to rotation and pull-out

Ideal for materials susceptible to cracking - Design Guideliness

Sizes: M4 – M12 (#8 – 1/2″)

Lengths: Per customer design

Thread Styles: Machine screw; others as specified

Specials: Completed assemblies available

- Features