TAPTITE 2000® FASTENERS

High performance thread rolling screws specially designed to lower your in-place fastening costs.

Taptite 2000® screws form internal threads into plain holes in ductile materials upon initial installation, which:

– Eliminates the need to pre-tap the nut member

– Reduces problems associated with assembling screws and bolts into pre-tapped holes, such as cross-threading

-

-

-

-

- Features

Trilobular™ Configuration

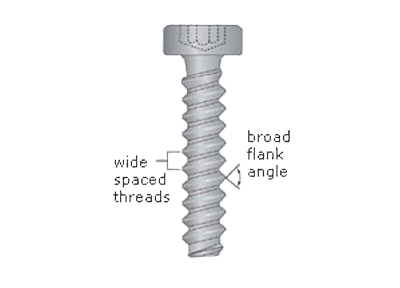

Radius Profile™ Thread

Roll Forms Own Work-hardened Mating Threads

Available with TORX PLUS® Drive System - Benefits

Reduces friction

Increases prevailing torque

Resists loosening caused by vibration

Lower end load requirements

Lowers thread forming torque without sacrificing performance

Higher, more uniform drive-to-fail ratio

Increased drive-to-strip ratio

Resist internal thread stripping

Excellent axial alignment

Results in higher strength internal threads due to the cold flow/work hardening that occurs during the forming of the nut thread

Significantly extends tool life

Ideal drive system for maximum torque transfer - Design Guidelines

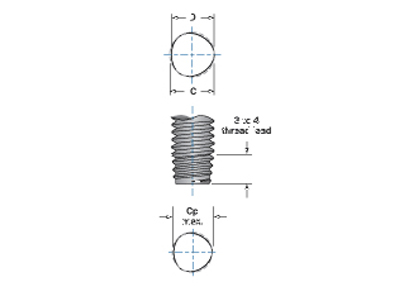

Thread Style: Radius Profile™ thread with twin-lead helix angle

Head Styles: Undercut head

Drive Systems: All styles available; TORX PLUS® Drive System recommended

Point Style: Standard Taptite® point; also available in SP™ (short point) and CA point

Materials: Low carbon steel, medium carbon steel, alloy steel, stainless steel

Finishes: Will accept all typical finishes

- Features

-

-

-

-

-

-

-

- Features

Trilobular™ Configuration

Radius Profile™ Thread

Roll Forms Own Work-hardened Mating Threads

Available with TORX PLUS® Drive System - Benefits

Reduces friction

Increases prevailing torque

Resists loosening caused by vibration

Lower end load requirements

Lowers thread forming torque without sacrificing performance

Higher, more uniform drive-to-fail ratio

Increased drive-to-strip ratio

Resist internal thread stripping

Excellent axial alignment

Results in higher strength internal threads due to the cold flow/work hardening that occurs during the forming of the nut thread

Significantly extends tool life

Ideal drive system for maximum torque transfer - Design Guidelines

Thread Style: Radius Profile™ thread with twin-lead helix angle

Head Styles: Undercut head

Drive Systems: All styles available; TORX PLUS® Drive System recommended

Point Style: Standard Taptite® point; also available in SP™ (short point) and CA point

Materials: Low carbon steel, medium carbon steel, alloy steel, stainless steel

Finishes: Will accept all typical finishes

- Features

-

-

-