FASTITE® 2000™

Sheet metal thread forming screws and bolts created to deliver cost-effective and optimum joint performance in sheet metal applications as thin as 0.7mm (.028 in.).

Fastite® 2000™ screws feature a thread-forming design created to deliver cost-effective and optimum joint performance in sheet metal applications as thin as 0.7mm (.028 in.) This unique design employs many of the design innovations for high-performance thread-rolling fasteners featured in Taptite 2000® fasteners.

- Features

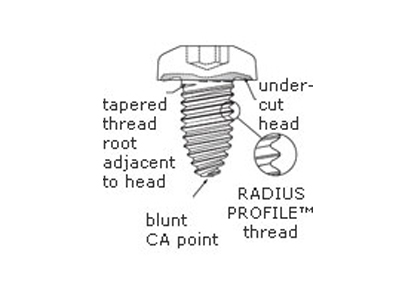

Tapered Thread Root Adjacent to Head

Undercut Head

Radius Profile™ Thread with Twin-lead Helix Angle

Blunt CA Point

Trilobular™ Body

Available with TORX PLUS® Drive System - Benefits

Maintains full thread major diameter close to the bearing surface

Absorbs material extruded by the screw and increases the underhead contact area to enhance thread engagement and resistance to stripping

Provides a mating thread system in which diametrically opposed threads are engaged

Provides low thread-forming torque with high resistance to failure

Head seats squarely compared to off-axis tendency of sheet metal screws

Allows entry into small holes to create self-extrusion of the sheet metal and to increase resistance to stripping

Provides resistance to loosening caused by vibration.

Significantly extends tool life

Ideal drive system for maximum torque transfer - Design Guidelines

Thread Style: Radius Profile™ thread with twin-lead helix angle

Head Styles: Hex flange undercut head

Drive Systems: All styles available; TORX PLUS® Drive System recommended

Point Style: Blunt CA point

Materials: Low carbon steel, medium carbon steel, alloy steel, stainless steel

Finishes: Will accept all typical fastener finishes

- Features

Tapered Thread Root Adjacent to Head

Undercut Head

Radius Profile™ Thread with Twin-lead Helix Angle

Blunt CA Point

Trilobular™ Body

Available with TORX PLUS® Drive System - Benefits

Maintains full thread major diameter close to the bearing surface

Absorbs material extruded by the screw and increases the underhead contact area to enhance thread engagement and resistance to stripping

Provides a mating thread system in which diametrically opposed threads are engaged

Provides low thread-forming torque with high resistance to failure

Head seats squarely compared to off-axis tendency of sheet metal screws

Allows entry into small holes to create self-extrusion of the sheet metal and to increase resistance to stripping

Provides resistance to loosening caused by vibration.

Significantly extends tool life

Ideal drive system for maximum torque transfer - Design Guidelines

Thread Style: Radius Profile™ thread with twin-lead helix angle

Head Styles: Hex flange undercut head

Drive Systems: All styles available; TORX PLUS® Drive System recommended

Point Style: Blunt CA point

Materials: Low carbon steel, medium carbon steel, alloy steel, stainless steel

Finishes: Will accept all typical fastener finishes