PATENTS & TRADEMARKS

I valori del Gruppo, le competenze interne e la stretta collaborazione con i Clienti, ciascuno leader nel proprio mercato di riferimento, ha comportato la crescita del Gruppo dal punto di vista tecnico e tecnologico rendendolo, nei decenni, vero e proprio first mover nel settore dei fastener.

Ne sono prova gli oltre 130 brevetti sviluppati negli anni, a cui si aggiungono innumerevoli trademark e trattamenti che costituiscono veri e propri punti di riferimento per il settore dei fasteners: Torx®, Strux®, Z-Form®, Paralobe™, Magnaseal®, Everprotect®, Esascanalata®, Neverfriction™ – solo per citarne alcuni.

Materiali, rivestimenti, tecnologie, design dei prodotti sono al centro dell’analisi di decine di professionalità integrate che oltre a lavorare in coordinamento nei centri siti in Italia, USA e Brasile, si confrontano continuamente con università e centri di ricerca. Il tutto, da sempre, ponendo particolare attenzione anche all’aspetto green dell’attività.

HEXET™

IDEAL FOR SCREWDRIVER INTERCHANGEABILITY

DESIGN: Socket Maximization; Big socket Vs External Diameter and socket depth

INTERCHANGEABILITY: Ensure functional maneuverability with three different bits: HEXET, TORX and HEXAGONAL bit

PERFORMANCE: Maximum efficiency in torque transmission with Hexet bit; plastic clamping ensured also with Torx and Hexagonal bits

SERVICE-AUTOMATION: Optimized for service requirements and automatic assemblies; Torx and Hexagonal are non-emergency bits

IDEAL FOR SCREWDRIVER INTERCHANGEABILITY

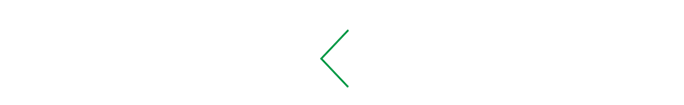

HEXATRAC™

WEIGHT REDUCED DRIVE SYSTEM

DESIGN: Mass removed from non-essential areas of hex drive system

COMPATIBILITY: Utilizes existing common hex socket drive strategies

PERFORMANCE: Reliable torque transmission and clamp load

generation

IDEAL FOR WEIGHT REDUCTION WITH HEX DRIVE SYSTEMS

ESASCALANATA®

SIX-SPLINE DRIVE KEY

LIGHTNESS: Material only where needed, socket maximization, height reduction

PERFORMANCE: 100% efficiency in torque transmission through radial planes

COMPATIBILITY: The profile has been designed to ensure its maneuverability also with standard hexagonal wrenches

AUTOMATION: Optimization for automatic assembly and precision tightening with angle control

IDEAL FOR WEIGHT REDUCTION

TORX®

MARKET LEADING DRIVE SYSTEM/strong>

DESIGN: Eliminates cam out failures

PERFORMANCE: Enhance product reliability over common drive systems; Eliminates wobble; Reduces total assembly costs and drive bit life compared to competing drive systems

PRODUCTIVITY: Increases productivity by reducing worker fatigue due to lower end loads during installation

PERFORMS BETTER THAN MOST DRIVE SYSTEMS

TORX PLUS® DRIVE SYSTEM

ENHANCED MARKET LEADING DRIVE SYSTEM

DESIGN: Same benefits as Torx® drive system with additional enhancements

PERFORMANCE: 20% average improvement in driver bit torsional strength; Greater bit life than Torx® drive system; Increased bit strength allows for higher removal torque capability

DESIGN OPTION: Low profile external drive versions to reduce weight and minimize clearance need; Oversize recess lobe option for heavy; Autosert version to improve automation coatings; Tamper resistant version to improve security

IDEAL FOR APPLICATIONS NEEDING BETTER TOOL LIFE THAN TORX® DRIVE SYSTEM

TORX® PARALOBE™ DRIVE SYSTEM

NEXT GENERATION LEADING DRIVE SYSTEM

DESIGN: Same benefits and design options as Torx Plus® drive system with additional enhancements

PERFORMANCE: 20% greater drive bit torsional strength than Torx Plus® Drive System; 20% greater drive system strength than Torx Plus®; 100% greater finite drive bit fatigue life than Torx Plus® Drive System Drive System; Potential reduction in recess coating damage and resulting corrosionPlus® Drive System

IDEAL FOR APPLICATIONS THAT NEED HIGHER TORQUE TRANSFER THAN

TORX PLUS® DRIVE SYSTEMS CAN MANAGE

MAGNASEAL®

SELF SEALING THREADED PLUG

DESIGN: Eliminates sealing washers, o-rings, and thread sealing compounds

PERFORMANCE: high pressure capability; eliminates spiral leakage; Liquid tight sealing improves with re-use

COMPATIBILITY: Ideal for aluminum, cast iron, and steel applications

IDEAL FOR SIMPLIFYING SERVICEABLE PLUG APPLICATIONS

Z-FORM®

ENGINEERED FASTENER FOR HIGH SHEAR APPLICATIONS

DESIGN: Can compensate for true position offsets in joint components; Allows for the use of fewer or smaller fasteners in many applications

PERFORMANCE: Prevents lateral slippage in joints subjected to high shear loads; Extremely high level of torque transfer capacity for drive line joints (e.g. ring gears, half shafts, etc.)

IDEAL FOR MANAGING HIGH SHEAR FORCES

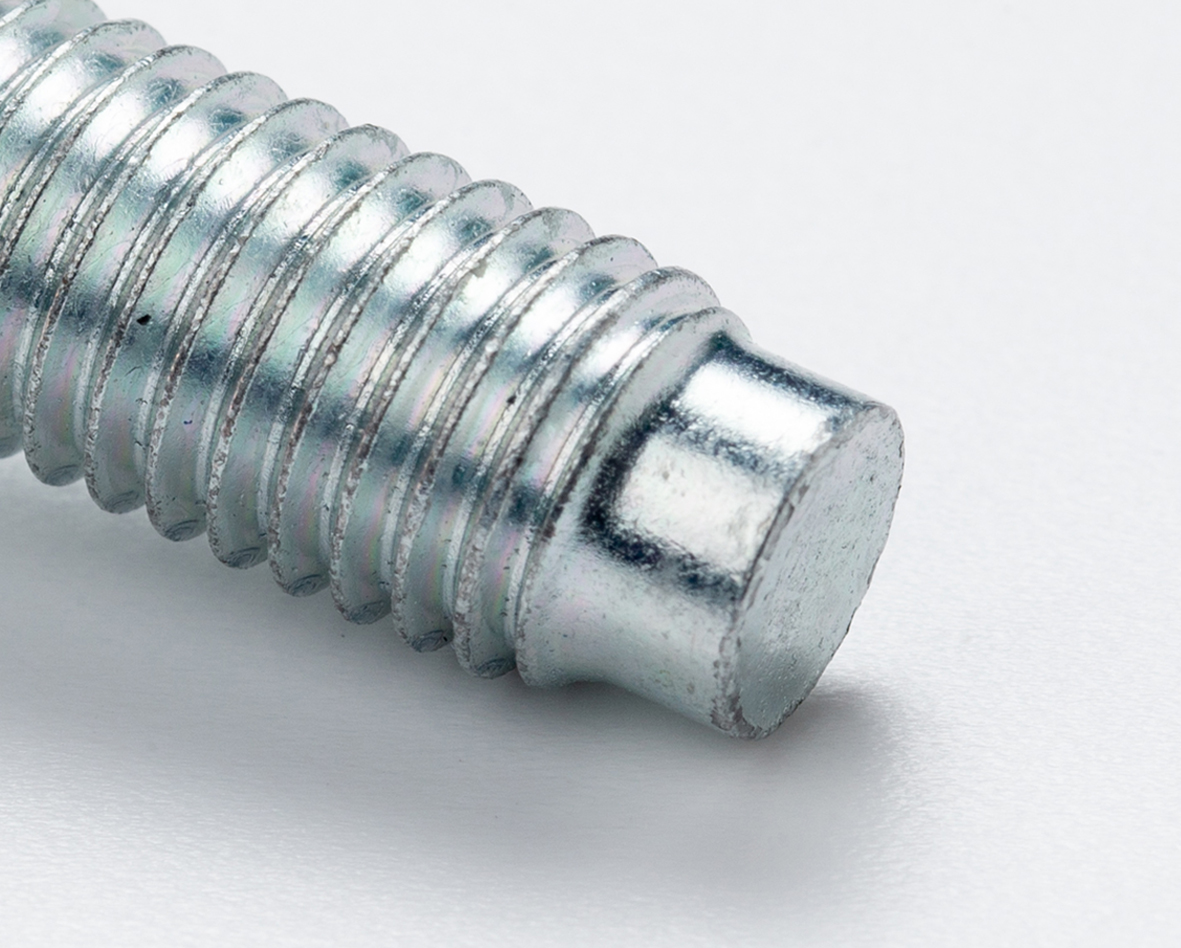

FLOGRUV™

FLUID TRANSFER BOLT

DESIGN: no internal passages which can become clogged with coating or debris

PERFORMANCE: No hidden burrs which can dislodge and cause system failures

APPLICATION: External fluted geometry is easier to clean

IDEAL ALTERNATIVE TO DRILLED BANJO BOLTS FOR FLUID MANAGEMENT APPLICATION

STRUX®

CLINCH STUDS AND NUTS

DESIGN: facilitates assembly of hard to reach component; eliminates welding operations; Accommodates sheet thickness greater than 1.0mm

COMPATIBILITY: Can be installed in-die with most existing equipment

OPTIMAL PERFORMANCE FOR SHEET METAL FASTENING APPLICATIONS

MAGGCERT®

THREADED FORMING INSERT ALLOWING SERVICEABILITY IN MAGNESIUM APPLICATIONS

DESIGN: Features high torque capacity internal TORX PLUS® Drive; Minimal debris generation

SERVICE: Ease of service of magnesium assemblies with multiple re-insertions

IDEAL FOR MAGNESIUM ASSEMBLIES REQUIRING FREQUENT SERVICING

MAG-FORM®

THREAD FORMING FASTENER FOR MAGNESIUM

DESIGN:Requires only pre-drilled or as-cast holes

PERFORMANCE:) Minimal debris generation; Forms strong threads in brittle materials

SERVICE: Allows for removal and insertion

IDEAL FOR LIGHTWEIGHTING STRATEGIES FOR LOW-DUCTILE MATERIALS

TECNOSIX®

HV, HR, HRC | METAL CONSTRUCTIONS BOLTS

PERFORMANCE: Give high security to big structures; Precise Torque and Tensioning with known K coefficient; Increased fatigue performances; Improve durability and shock resistance at low temperature of assemblies; Optimize assembling performance with less bolts

AUTOMATION-SERVICE: Replace with no major, no riveted joints

TECNOSIX: IDEAL FOR METAL CONSTRUCTION JOINTS

VBA®

STRONG WOOD JOINT

PERFORMANCE: Excellent adjustment of supports; Higher screwing speed; Structural flexibility deu to Special Heat treatment

COMPATIBILITY: Wood applications also high thickness and hardwood

AUTOMATION-SERVICE: Reduced time and aid to assembly

VBA: IDEAL FOR WOOD APPLICATIONS

CLEARANCE RECOVERY

SCARCELY PRECISE JOINT IN METAL SHEET SHELLS

FULLY FUNCTIONAL: complete play recovery and zero vibrations

EASY TO USE: can be externally tightened with a standard wrench

VERSATILITY: can be used also on scarcely precise joints, and recovers several mm of play

CUSTOMIZATION: produced in different sizes on demand

IDEAL FOR TIGHTENING STEEL PLATE SHELLS

EVERPROTECT®

MULTI-LAYER COATING

APPEARANCE: High quality finishes in both matte and gloss ideal for use with wheels

PROTECTION: High resistance against environmental corrosion, protects against acids and aggressive cleaners, thermal stability under use.

PERFORMANCE: Stable coefficient of friction up to 20 tightening cycles

IDEAL FOR EXTERNAL HIGHLY VISIBLE FASTENERS

NEVERFRICTION™ | developed in collaboration with GLOMAX