PATENTS & TRADEMARKS

The Group’s values, internal expertise and close collaboration with customers – each a leader on its own reference market – have fostered the Group’s growth from a technical and technological viewpoint and, over the decades, have made it a first mover in the fastener sector.

Proof of this are the 130+ patents developed over the years, to which must be added countless trademarks and treatments that constitute real points of reference for the fasteners sector: Torx®, Strux®, Z-Form®, Paralobe™, Magnaseal®, Everprotect®, Esascanalata®, Neverfriction™ – to name only a few.

Materials, coatings, technologies and product design are at the heart of the analysis of dozens of integrated professionals who, besides working in a coordinated way in the centres located in Italy, the USA and Brazil, constantly collaborate with universities and research centres. All this while always paying special attention to the green aspect of the business activity.

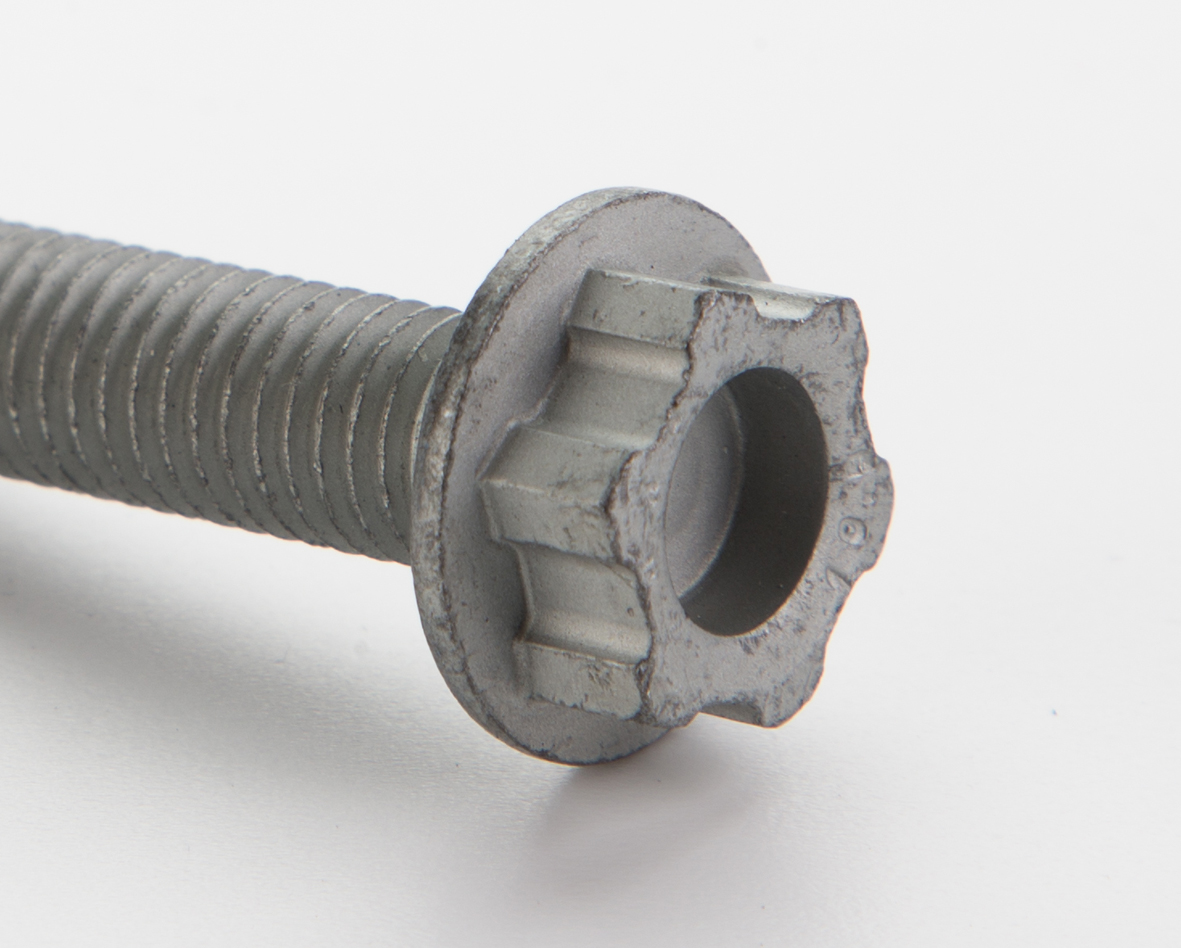

HEXET™

IDEAL FOR SCREWDRIVER INTERCHANGEABILITY

DESIGN: Socket Maximization; Big socket Vs External Diameter and socket depth

INTERCHANGEABILITY: Ensure functional maneuverability with three different bits: HEXET, TORX and HEXAGONAL bit

PERFORMANCE: Maximum efficiency in torque transmission with Hexet bit; plastic clamping ensured also with Torx and Hexagonal bits

SERVICE-AUTOMATION: Optimized for service requirements and automatic assemblies; Torx and Hexagonal are non-emergency bits

IDEAL FOR SCREWDRIVER INTERCHANGEABILITY

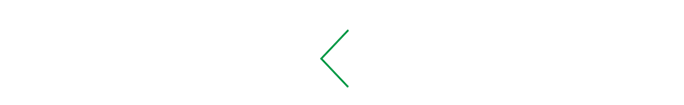

HEXATRAC™

WEIGHT REDUCED DRIVE SYSTEM

DESIGN: Mass removed from non-essential areas of hex drive system

COMPATIBILITY: Utilizes existing common hex socket drive strategies

PERFORMANCE: Reliable torque transmission and clamp load

generation

IDEAL FOR WEIGHT REDUCTION WITH HEX DRIVE SYSTEMS

ESASCALANATA®

SIX-SPLINE DRIVE KEY

LIGHTNESS: Material only where needed, socket maximization, height reduction

PERFORMANCE: 100% efficiency in torque transmission through radial planes

COMPATIBILITY: The profile has been designed to ensure its maneuverability also with standard hexagonal wrenches

AUTOMATION: Optimization for automatic assembly and precision tightening with angle control

IDEAL FOR WEIGHT REDUCTION

TORX®

MARKET LEADING DRIVE SYSTEM/strong>

DESIGN: Eliminates cam out failures

PERFORMANCE: Enhance product reliability over common drive systems; Eliminates wobble; Reduces total assembly costs and drive bit life compared to competing drive systems

PRODUCTIVITY: Increases productivity by reducing worker fatigue due to lower end loads during installation

PERFORMS BETTER THAN MOST DRIVE SYSTEMS

TORX PLUS® DRIVE SYSTEM

ENHANCED MARKET LEADING DRIVE SYSTEM

DESIGN: Same benefits as Torx® drive system with additional enhancements

PERFORMANCE: 20% average improvement in driver bit torsional strength; Greater bit life than Torx® drive system; Increased bit strength allows for higher removal torque capability

DESIGN OPTION: Low profile external drive versions to reduce weight and minimize clearance need; Oversize recess lobe option for heavy; Autosert version to improve automation coatings; Tamper resistant version to improve security

IDEAL FOR APPLICATIONS NEEDING BETTER TOOL LIFE THAN TORX® DRIVE SYSTEM

TORX® PARALOBE™ DRIVE SYSTEM

NEXT GENERATION LEADING DRIVE SYSTEM

DESIGN: Same benefits and design options as Torx Plus® drive system with additional enhancements

PERFORMANCE: 20% greater drive bit torsional strength than Torx Plus® Drive System; 20% greater drive system strength than Torx Plus®; 100% greater finite drive bit fatigue life than Torx Plus® Drive System Drive System; Potential reduction in recess coating damage and resulting corrosionPlus® Drive System

IDEAL FOR APPLICATIONS THAT NEED HIGHER TORQUE TRANSFER THAN

TORX PLUS® DRIVE SYSTEMS CAN MANAGE

MAGNASEAL®

SELF SEALING THREADED PLUG

DESIGN: Eliminates sealing washers, o-rings, and thread sealing compounds

PERFORMANCE: high pressure capability; eliminates spiral leakage; Liquid tight sealing improves with re-use

COMPATIBILITY: Ideal for aluminum, cast iron, and steel applications

IDEAL FOR SIMPLIFYING SERVICEABLE PLUG APPLICATIONS

Z-FORM®

ENGINEERED FASTENER FOR HIGH SHEAR APPLICATIONS

DESIGN: Can compensate for true position offsets in joint components; Allows for the use of fewer or smaller fasteners in many applications

PERFORMANCE: Prevents lateral slippage in joints subjected to high shear loads; Extremely high level of torque transfer capacity for drive line joints (e.g. ring gears, half shafts, etc.)

IDEAL FOR MANAGING HIGH SHEAR FORCES

FLOGRUV™

FLUID TRANSFER BOLT

DESIGN: no internal passages which can become clogged with coating or debris

PERFORMANCE: No hidden burrs which can dislodge and cause system failures

APPLICATION: External fluted geometry is easier to clean

IDEAL ALTERNATIVE TO DRILLED BANJO BOLTS FOR FLUID MANAGEMENT APPLICATION

STRUX®

CLINCH STUDS AND NUTS

DESIGN: facilitates assembly of hard to reach component; eliminates welding operations; Accommodates sheet thickness greater than 1.0mm

COMPATIBILITY: Can be installed in-die with most existing equipment

OPTIMAL PERFORMANCE FOR SHEET METAL FASTENING APPLICATIONS

MAGGCERT®

THREADED FORMING INSERT ALLOWING SERVICEABILITY IN MAGNESIUM APPLICATIONS

DESIGN: Features high torque capacity internal TORX PLUS® Drive; Minimal debris generation

SERVICE: Ease of service of magnesium assemblies with multiple re-insertions

IDEAL FOR MAGNESIUM ASSEMBLIES REQUIRING FREQUENT SERVICING

MAG-FORM®

THREAD FORMING FASTENER FOR MAGNESIUM

DESIGN:Requires only pre-drilled or as-cast holes

PERFORMANCE:) Minimal debris generation; Forms strong threads in brittle materials

SERVICE: Allows for removal and insertion

IDEAL FOR LIGHTWEIGHTING STRATEGIES FOR LOW-DUCTILE MATERIALS

TECNOSIX®

HV, HR, HRC | METAL CONSTRUCTIONS BOLTS

PERFORMANCE: Give high security to big structures; Precise Torque and Tensioning with known K coefficient; Increased fatigue performances; Improve durability and shock resistance at low temperature of assemblies; Optimize assembling performance with less bolts

AUTOMATION-SERVICE: Replace with no major, no riveted joints

TECNOSIX: IDEAL FOR METAL CONSTRUCTION JOINTS

VBA®

STRONG WOOD JOINT

PERFORMANCE: Excellent adjustment of supports; Higher screwing speed; Structural flexibility deu to Special Heat treatment

COMPATIBILITY: Wood applications also high thickness and hardwood

AUTOMATION-SERVICE: Reduced time and aid to assembly

VBA: IDEAL FOR WOOD APPLICATIONS

CLEARANCE RECOVERY

SCARCELY PRECISE JOINT IN METAL SHEET SHELLS

FULLY FUNCTIONAL: complete play recovery and zero vibrations

EASY TO USE: can be externally tightened with a standard wrench

VERSATILITY: can be used also on scarcely precise joints, and recovers several mm of play

CUSTOMIZATION: produced in different sizes on demand

IDEAL FOR TIGHTENING STEEL PLATE SHELLS

EVERPROTECT®

MULTI-LAYER COATING

APPEARANCE: High quality finishes in both matte and gloss ideal for use with wheels

PROTECTION: High resistance against environmental corrosion, protects against acids and aggressive cleaners, thermal stability under use.

PERFORMANCE: Stable coefficient of friction up to 20 tightening cycles

IDEAL FOR EXTERNAL HIGHLY VISIBLE FASTENERS

NEVERFRICTION™ | developed in collaboration with GLOMAX